Reaming Percussion Revolver Cylinder Chamber Throats

An important part in revolver accuracy.

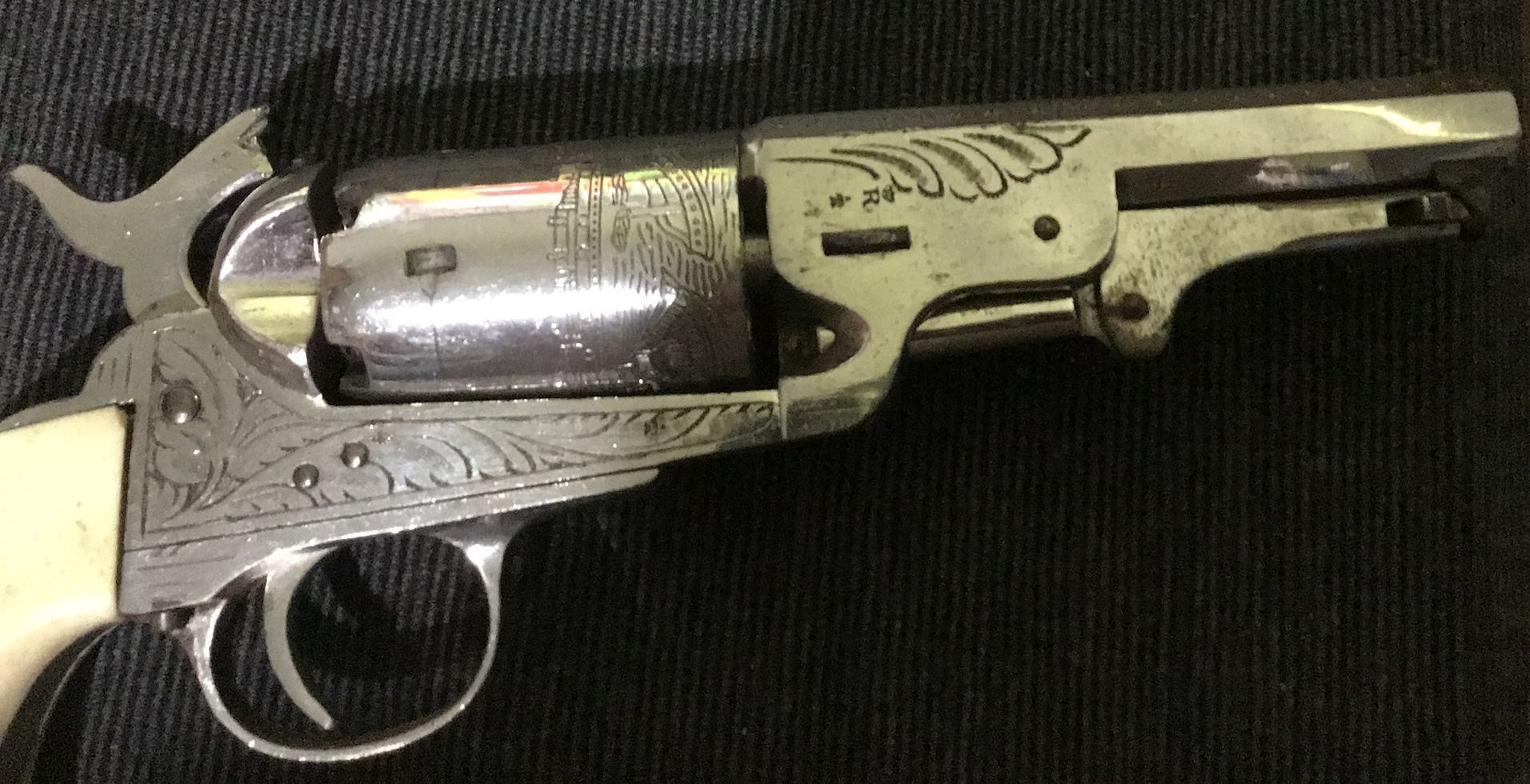

Perussion revolver accuracy can sometimes be a source of constant aggravation. Shooters experiment with various loads and projectiles trying to achieve groups that don’t resemble buckshot from a skeet gun. Some percussion revolvers exhibit good accuracy with little or no effort at all, while others of seemingly the same quality will not shoot a decent group no matter the amount of work and frustration involved. There are many variables in getting a percussion revolver to shoot accurately, and most gun makers do a decent job, considering these are replica revolvers. With everything that the bullet must endure before leaving the muzzle of a percussion revolver, it is sometimes amazing that they can place a bullet close to the intended target. In this section, I will attempt to address one particular, and the most crucial variable: the cylinder chamber throat diameters, which are often overlooked. The throat gives the bullet its first stabilizing guidance, and many people better than I have demonstrated that it is critical to good accuracy – perhaps more than the bore itself!

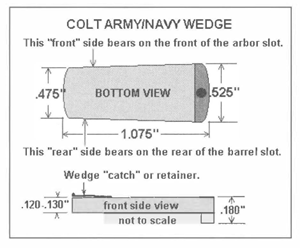

Problems occur that are detrimental to accuracy when the cylinder chamber is not sized properly in relation to the groove diameter of the barrel. The cylinder chamber should be the same as, or slightly over, the groove diameter. When a percussion revolver cylinder chamber is oversized, the bullet does indeed undergo a process of deformation upon firing. As the powder ignites, the rapidly expanding gases create immense pressure behind the bullet. This pressure causes the base of the bullet to expand slightly, helping to seal the chamber and prevent gas leakage. As the bullet moves through an oversized chamber, it may experience some deformation due to the excess space. However, this deformation is generally minimal and not uniform around the bullet. When the bullet reaches the cylinder throat (the transition between the chamber and the barrel), it begins to encounter a slight constriction. This area is typically designed to be slightly smaller than the chamber but still larger than the bore diameter.

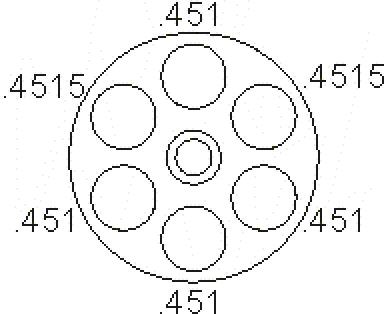

Ideally, the chamber throat (the exit point of the chamber) should be slightly larger than the bullet diameter, typically by 0.001" to 0.002". This allows for proper bullet alignment and engagement with the rifling. If the chamber is too large, it can lead to bullet misalignment when entering the barrel, potentially causing accuracy issues. Consistency across all chambers is important. Variations in chamber sizes can result in inconsistent accuracy from one chamber to another.

When a chamber is too large, the bullet will be "bumped up" upon firing to fill the chamber mouth and then squeezed back down upon entering the bore. The opposite of this condition is when the cylinder chamber mouths are undersized, or smaller than the groove diameter of the barrel. In this situation, the bullet is squeezed down upon entering the cylinder chamber mouth and then bumped up when entering the barrel to fill the groove diameter. The problem occurs when the bullet, which is now under size for the barrel, does not bump up to proper diameter. This happens hard cast bullets, leaving a bullet traveling down the bore without a good seal or proper rifling engagement, resulting in excessive bore leading and imperfect alignment upon leaving the muzzle, and the result at the target is poor accuracy.

It would seem that after over 180 years of revolver manufacture, that those involved in the process would have settled upon a proper diameter for cylinder chamber mouths in relation to barrel dimensions, but with replica percussion revolvers, it just isn’t so. Oddly, the problem occurs most often with our replica percussion revolvers in common use; the Pietta and Uberti revolvers. These replicas have been with us for over 70 years, and still guns are being shipped daily with under size cylinder throats. The Pietta .44 caliber revolvers should be coming with .440 lands and .442 to .450 grooves with chamber diameters of .446 to .449 according the Dixie Gun Works 2019 catalog. The .36 caliber revolvers should have .360 lands and .372 grooves with .367 chambers. But if you want your projectile to fully engage the grooves, they are not going to. So, to improve the accuracy of your revolver, you may need to ream your chamber mouth. This is not a difficult task for the mechanically minded, but if you are not mechanically minded, you will need to have a gunsmith do it for you.

The absolute best method to measuring your cylinder chamber throats is with a very good set of pin gages. They can be expensive but are well worth the price if you have multiple caliber revolvers. But if you have no pin gages at hand, then you can slug your chambers and barrel to get the diameters. This method is not as accurate, but as long as your chamber throats end up larger than your barrel diameter by at least .001, it will be fine. After slugging your barrel and cylinder chambers, (refer to the PDF file) and you find that it is necessary, ream the chamber mouths as per the instructions provided with your reamer. The procedure is very simple, and all work is done easily by hand. It basically involves fitting the reamer to the cylinder throat, oiling the tool, and turning the T-handle or drill press. Your cylinder mouths will not need to be more than .001 to .003 larger than the groove diameter of your barrel. So if your barrel groove measures out at .450, then your chamber throats will not need to be any large than .451, for example. When reaming the cylinder chamber mouths, it is a common practice to only go as deep as ball diameter/bullet length (conicals), or as deep as the projectile is seated into the chamber mouth with a small powder charge.

I suggest using a the Victor Machinery High Speed Steel Adjustable Blade Reamers to correct the problem of undersize cylinder mouths on .44 and .36 caliber revolvers. These reamers have been used successfully for many years to open up chamber mouths. The adjustable reamer is adjusted by loosening the nut at one end and tightening the nut at the other end. Due to its adjustability, it takes the place of many individual size reamers and can be used to progressively "open up" chambers. The reamer for .44 caliber chambers will open the mouths up from 0.4375 to 0.4688 and the reamer for .36 caliber chambers will open them up from 0.3438 to 0.3750. The only other item you may need is a T-handle to turn the reamer, such as is used to turn a threaded tap. Using the T-Handle is a much easier, especially if you do not have a drill press available.

There are untold thousands of good .44 and .36 revolvers that could benefit from this simple procedure, with more being made every day. If you have a .44 or .36 Colt or Remington, made by Uberti or Pietta, slug the barrel and chambers first to determine proper projectile size, then shoot it. If it is accurate, you are blessed. If it is not, the problem could be undersize cylinder mouths. The reamers will cost less than $20, and should do many cylinders and last a long time if used properly. You can find other types of reamers out there that are much more expensive, but the Victory Machinery Reamers will do the job just fine. You can find the Victory Machinery Reamers online at:

.44 caliber reamer:

RMBL-2A High Speed Steel Adjustable Blade Reamer, 7/16"-15/32"

.36 caliber reamer:

RMBL-5A High Speed Steel Adjustable Blade Reamer, 11/32"-3/8"

Web site designed & maintained by Cap and Ball Revolvers . Copyright 2024 and beyond. All rights reserved. All photos published on this site are the property of the author or are published with the permission of the authors. All copies and uses are prohibited.