Metal Fatigue in Replica Revolvers

Metal Fatigue in Replica Revolvers

I have always been an advocate for following reproduction revolver manufacturer's recommended load data for their revolvers. This load data is there for many reasons and one of those reasons is the reduction of metal fatigue. Metallurgists have determined that 80 percent of all firearm mechanical failures are fatigue failures. Fatigue failures occur after parts are subjected to repeated loads that, individually, may not be large enough to cause a failure. But, after many repetitions, however, a failure can occur. (American Rifleman, Metal-Fatigue Failures: Is Your Gun at Risk?, George E. Kontis, March 4, 2020)

Metal fatigue is the common name used to describe the unexpected failure of metal parts by progressive fracturing while in service. Metal fatigue is directly related to the number of stress cycles undergone by a part and the level of stress imposed on the part. So metal fatigue is more of a factor of stress than age. While metal does lose some of its strength over time, the loss is quite slow. It will only stretch so many times before it hardens and cracks.

Metal fatigue is based upon an engineering concept known as MTBF, or Mean (average) Time Between Failures. Since the time between failures for a component can depend on factors such as configurations, operating conditions, age, and other external factors, there isn't one “good” MTBF metric. In the case of replica revolvers, it refers to the number of pressure cycles a barrel, recoil shield or cylinder chamber will tolerate before its elastic limit is exceeded. When a pressure vessel fails, it is often not because it is currently being stressed beyond its design limit. It is usually about how much and how many times it was over stressed previously.

Studies have shown that infinite life for a metal part is possible if the local stresses in the part are kept below well-defined limits. Fatigue failures increase if parts have stress raising contours or if stress raisers such as notches, holes and keyways are put into the part. There is also a relationship between a metal’s ultimate tensile strength and hardness and its ability to handle fatigue loads. The higher the tensile strength and hardness the more likely it will fatigue if it is subject to high fluctuating loads. (Sondalini, M., Metal Fatigue Failure, Accendo Reliability)

Three factors are necessary to cause fatigue failure.

1. A maximum tensile stress of sufficient high value.

2. A large enough variation or fluctuation in the applied stress.

3. A sufficient large number of cycles of the applied stress.

Other variables and factors are: stress concentration, corrosion, temperature, overload, metallurgical structure, including residual stresses and combined stresses which tend to alter the conditions of fatigue. (Muhammad Ali Siddiqui, Fracture Mechanics & Failure Analysis: Fatigue, NED University of Engineering & Technology)

According to Armida Oradei, the chief metallurgist at Beretta USA, owner of Uberti, “This type of failure is prevented by Beretta via a meticulous selection of the materials during the design phase, followed by a careful analysis of all machining phases, to finally choosing the optimal finishing processes. Beretta, maker of Uberti revolvers, pays a great deal of attention to the prevention of fatigue failures, “… not only during all of the production phases but also to the material surface finishing. Components are machined with great attention in order to avoid machining marks or stress point areas, and they are then heat-treated with dedicated heat-treating cycles. Parts are then completed by passing through many finishing phases such as tumbling, polishing and sandblasting prior to advancing to their final surface finishing treatment. The care taken in the surface preparation is important not only to achieve esthetically attractive and uniform finished components, but also to improve surface characteristics that are of critical importance to avoid stress concentrator areas within the parts. Once the parts are completed, we follow up with magnetic particle inspection on all critical steel components of the firearm.” (Kontis, George E., Metal-Fatigue Failures: Is Your Gun at Risk?, March 4, 2020)

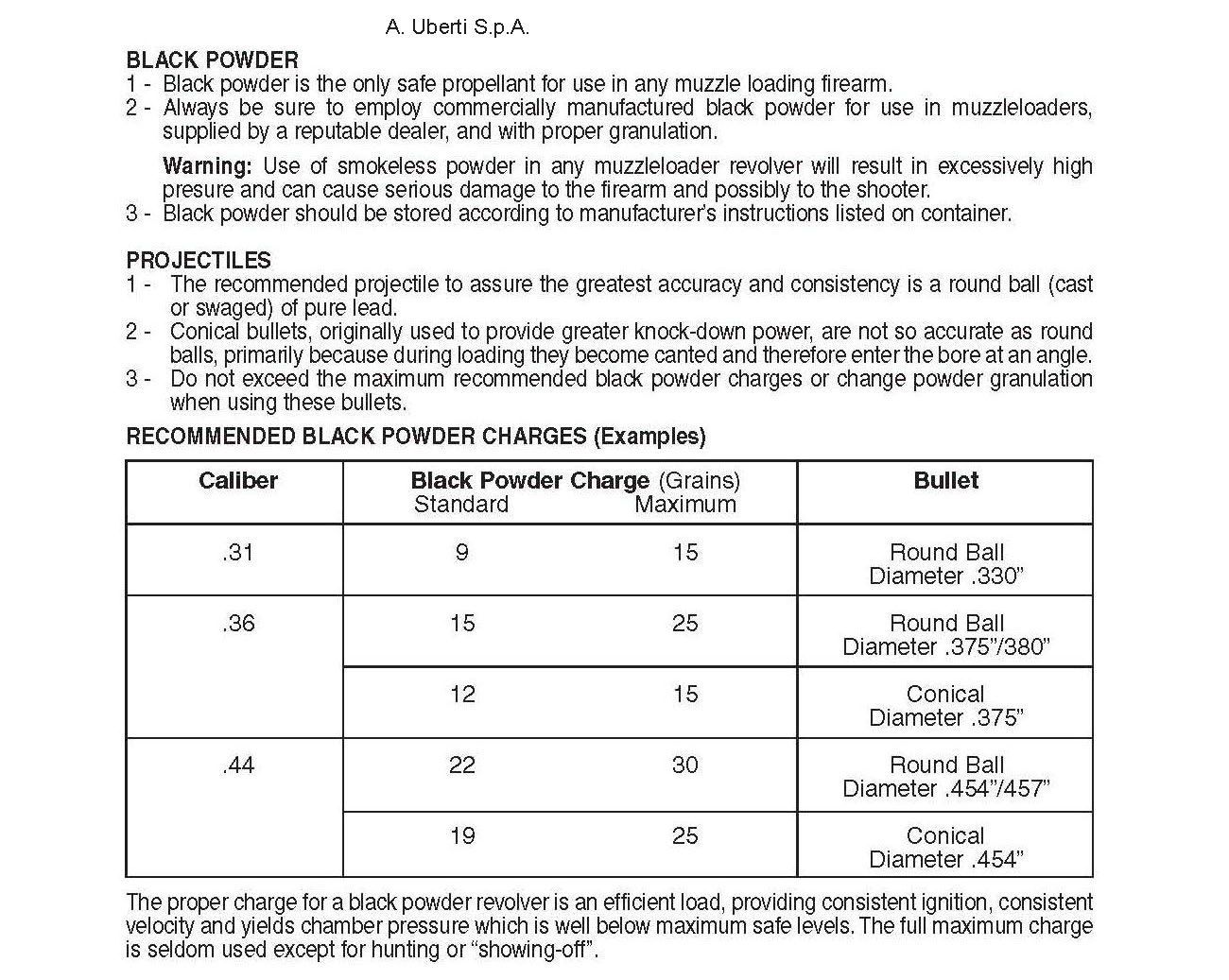

These revolvers are then tested and sent to the Italian proof house for further proofing and stamped by the proof house accordingly. Recommended load data is included in the manuals packed with every revolver indicating the load data the testing has confirmed is a safe, consistent load when used over many firings and to assist in preventing metal fatigue. There is nothing to suggest this process is much different at any other manufacturer.

4140 steel, which these replica revolvers are composed of, doesn't become brittle, it only increases in yield strength the harder the tempered condition while decreasing in ductility. So while it is possible to have the appearance of brittle failure it is only possible (assuming no heat treating cracks, sharp corners etc) when you have a load far, far beyond anything remotely reasonable and maybe with lots of slack to create an impact load.

Original Colt revolvers were blackheart malleable cast iron until the 1860 Colt came along. Colt advertised they used an alloy called "Silver Steel" in the Model 1860, allowing it to be stronger and lighter than the older model revolvers. Silver steel is also known as tool steel. It’s important to understand the differences between tool steel and 4140 steels. Tool steels offer superior strength but can be susceptible to chipping or breaking under shock loads, whereas 4140 steel has less strength but offers greater impact resistance due to its lower hardness level making it better suited for certain applications where impact loading may occur during use. So those who think today's metallurgy is far superior to the 1860's metallurgy, think again when it comes to replica revolvers.

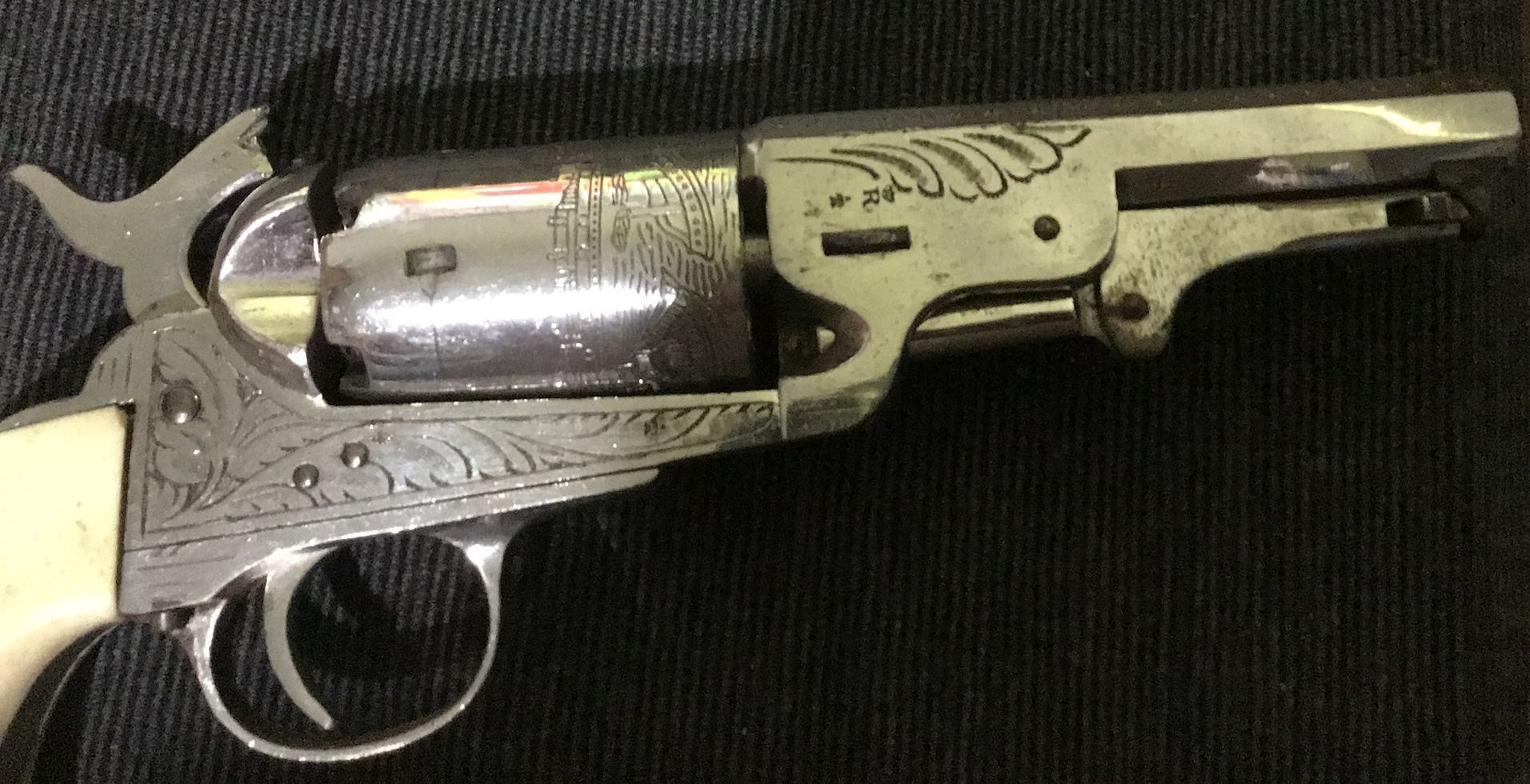

And then we have the brass frame revolvers that are of a much softer metal than 4140 steel. It is imperative that these brass framed revolvers not be exposed to repeated "hot loads". As seen in the photo of this blog post, they are more susceptible to metal fatigue than steel framed revolvers.

In conclusion, the repeated use of loads over the manufacturer's recommendations will continually add stress to a revolver and, over time, may eventually cause metal fatigue. It will then only be a matter of time before a catastrophic failure of that revolver, possibly harming you or the person next to you if at a range when the failure occurs. Load safely.........and NEVER use smokeless powder in a black powder firearm!