Colt and Chamfering Cylinder Chamber Mouths on Replica Revolvers

Chamfering Cylinder Chamber Mouths on Replica Revolvers.

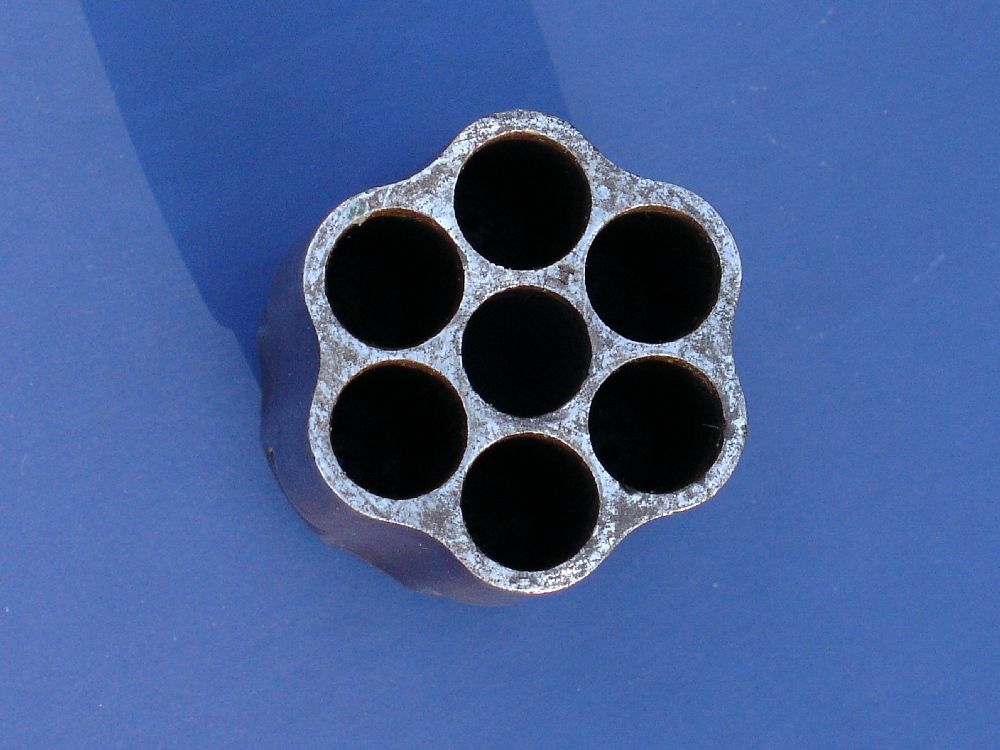

This idea of cutting a ring of lead while loading the ball is not actually a myth, but rather a real mechanical issue that can occur with today's replica revolver cylinder chambers and may have occured with original percussion revolvers. This phenomenon is related to the design and condition of the firearm, particularly when chambers are not properly chamfered or when pressure forces lead to fill gaps in the chamber. There is no real historical documentation for this practice of shaving a ring of lead off the ball while loading as far as I have been able to determine. Instead, a proper machined cylinder will have chamfered chamber mouths and there will be no ring cut with properly chamfered cylinder chamber mouths. Chamfering is the process of beveling the sharp edge of the chamber opening (mouth) to remove the sharp edge, which is what causes the ring of lead to be shaved off. Some have never heard of this concept before and some ask why one would chamfer the chamber mouths. There are actually two reasons for chamfering the mouths (opening) of the chambers in a black powder revolver cylinder.

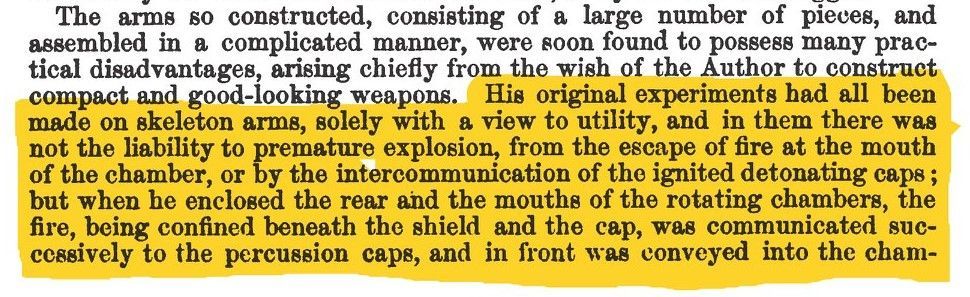

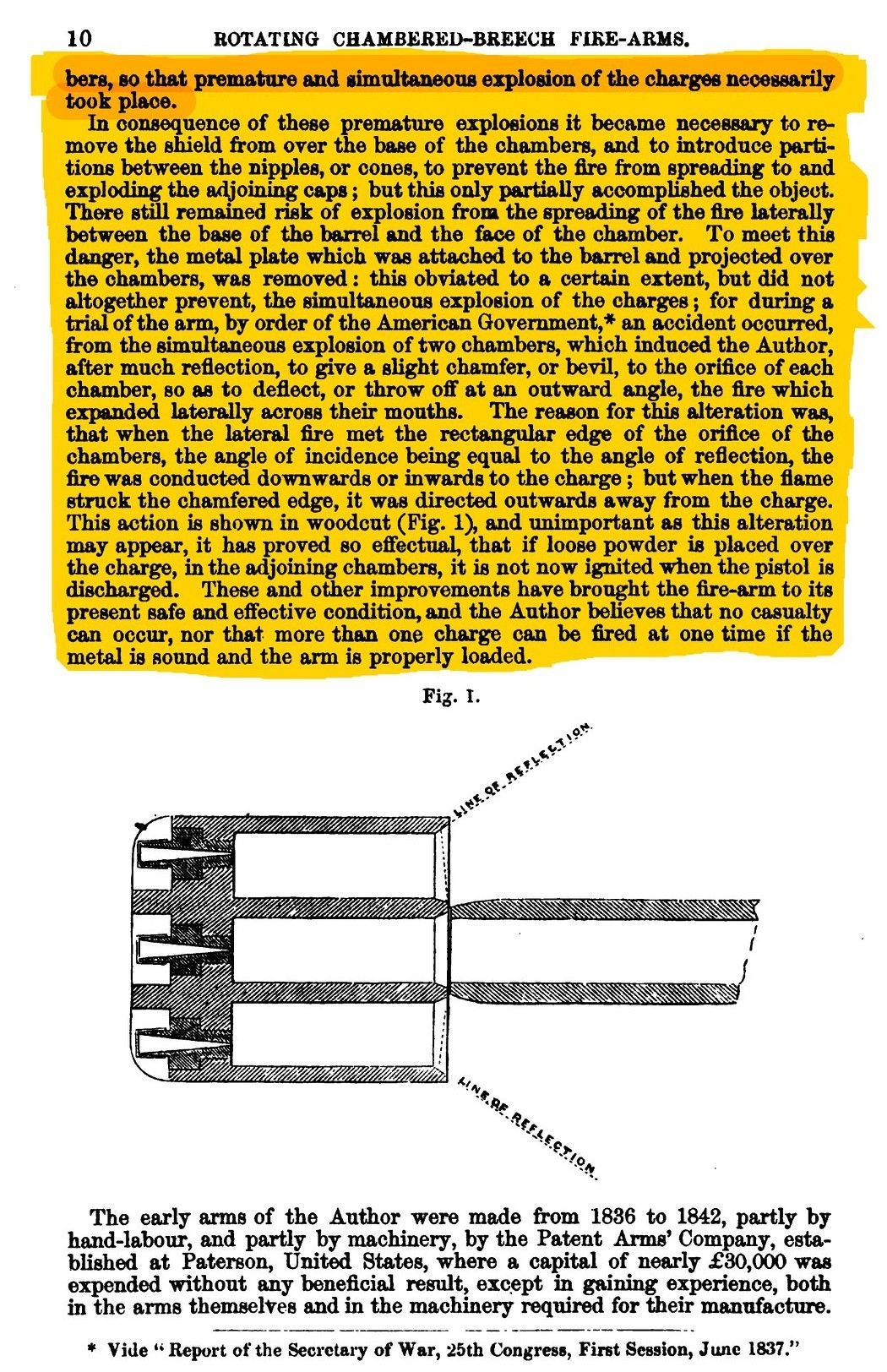

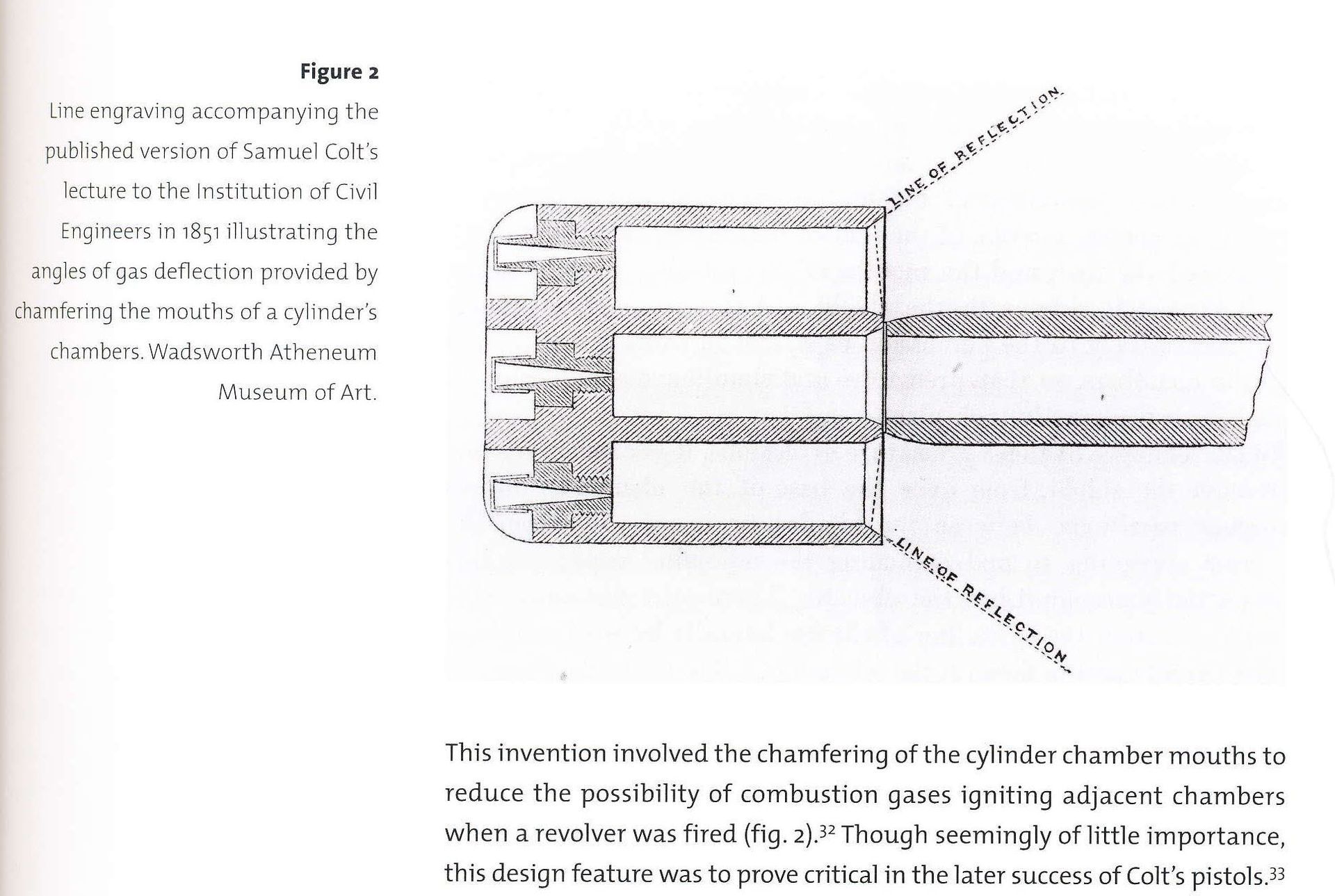

While doing research on this subject, I came across an interesting account of "premature simultaneous explosions" in "On The Application of Machinery to the Manufacture of Rotating Breech Firearms" by Samuel Colt. It seems that during the time of the manufacture and testing of the Colt Paterson, there was an issue with the "premature explosion from the escape of fire at the mouth of the chamber, or by the intercommunication of ignited detonating caps." This gives us the first reason for chamferig the chamber mouths, as this account from Samuel Colt tells us, it seems chainfire came from either end of the cylinder, from the chamber mouth end and from the cap end of the cylinder, as the account indicates. But Colt had a solution for this incidence of chainfire, which is explained in his own words below in the attached photos. This situation is also why we have shoulders between each chamber at the cone end of the cylinder.

The second reason for chamfering the chamber mouths was a reason that derived from competitive shooters who wanted to get more accuracy out of their revolvers, while at the same time eliminating chainfire.

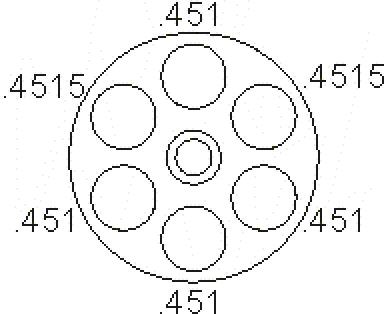

Chamfering, in this case, was done so that the projectiles would be swaged to fit the chamber rather than shaved to fit. Swaging the ball into the chamber gives more surface area engagement for the ball to better engage the rifling of the barrel, thereby increasing accuracy, while also not reducing the weight of the ball, which shaving a ring does. Shaving a ring off can also leave pockets of air between the ball and chamber wall, especially if non-swaged balls are being used. I have notice from firing before and after chamfering cylinder chambers that the projectiles were noticeably tighter in the chambers when swaged into the chamber rather than being shaved to fit. This is going to create a better seal, and, if using stouter loads, keep the projectiles in place while shooting, as well as maintain compression on the powder. And better compression also aids in reducing fouling.

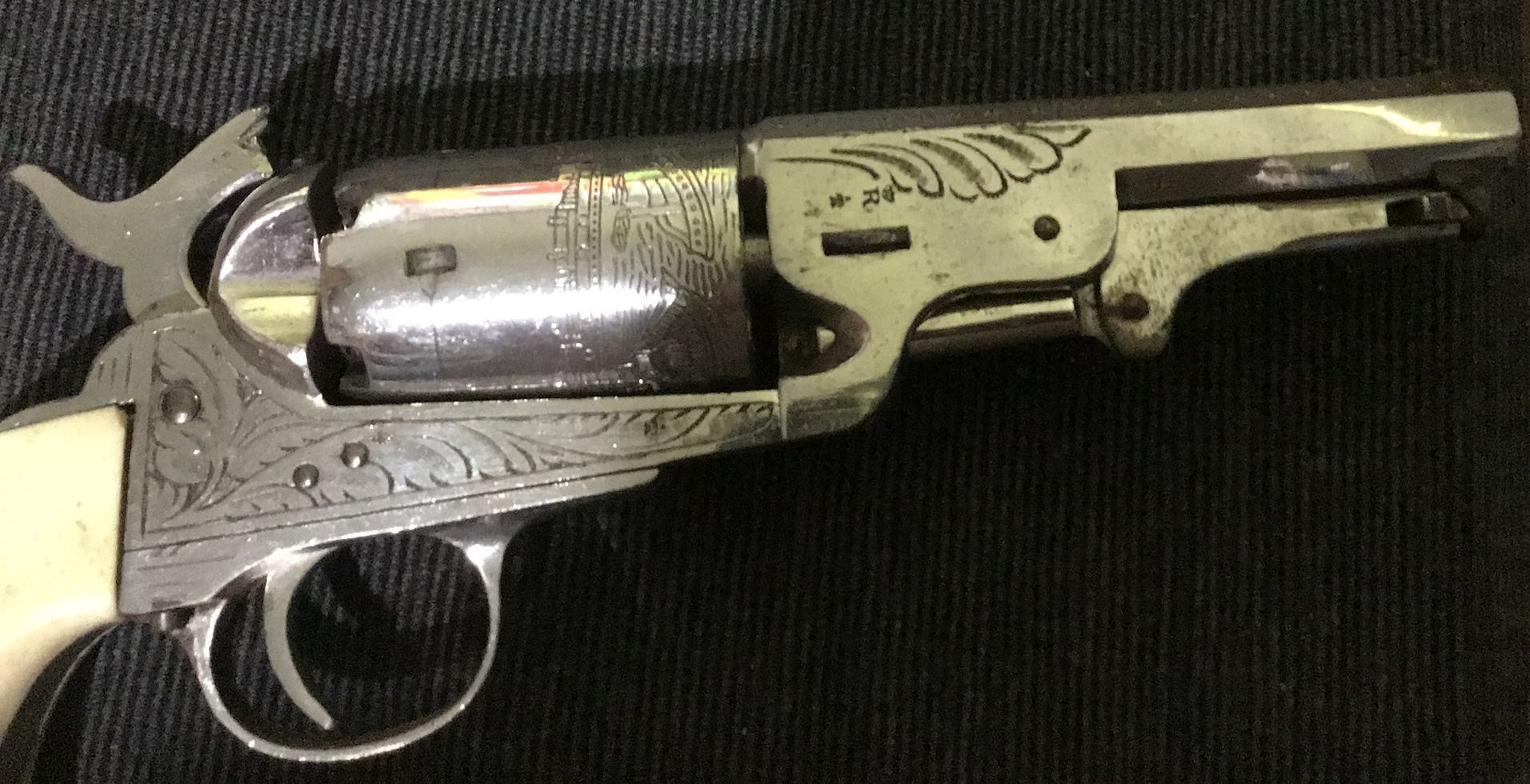

Not only did Colt chamfer cylinder chamber mouths, it was also done by H. S. North and Savage, inventor of the Savage revolvers.

Today, most all of the replica cap and ball revolvers do not have chamfered chamber mouths, but instead are made with straight walled chambers and sharp chamber mouth edges to simplify production and keep costs down. Yet, we have seen that originals, like Colts and Savages were made with chamfered chamber mouths. And the chamfered mouths did not shave lead rings which made for easier loading and the chambers swaged projectiles down to seal the chambers. The combination of chamfered chamber mouths and tapered chambers eliminated multiple "chain fires" (multiple simultaneous discharges) from the front of the cylinder. Today, with many replicas, "shaving a ring of lead", we see the necessity of chamfering the chamber mouths to eliminate this "ring of lead" so a full grain projectile can be loaded.

As demonstrated in the video above, the idea of a chamber mouth champfer is to only remove the sharp edge from the chamber mouth, thus reducing lead shaving when seating the round ball. I used a hand tool since you only want to remove a small amount, although a drill can be used as well as a drill press.

The chamfering tool I use is from Pacific Tool and Gauge. There are three pieces to the tool, the chamfering bit, the handle and the pilot. In the video I did not use a pilot for the bit, but it is better yo use one if you have never done any chamfering before. This particular tool here is for .44 caliber, but tools are available for various other calibers. They can be found at:

Chamfering bit - https://www.pacifictoolandgauge.com/Interchangeable-Pilot-MuzzleCylinder-45-Deg-ChamferingCrowning-Cutter_p_115846.html

Chamfering bit handle - https://www.pacifictoolandgauge.com/14-20-Interchangeable-Pilot-Muzzle-Chamfering-and-Crowning-Cutter-Handle_p_115818.html

Chamfering bit pilot - https://www.pacifictoolandgauge.com/Interchangeable-Pilots-for-Muzzle-ChamferingCrowning-Cutters_p_115849.html

Web site designed & maintained by Cap and Ball Revolvers . Copyright 2024 and beyond. All rights reserved. All photos published on this site are the property of the author or are published with the permission of the authors. All copies and uses are prohibited.