Classic Arms International Inc.

A Brief History of Classic Arms

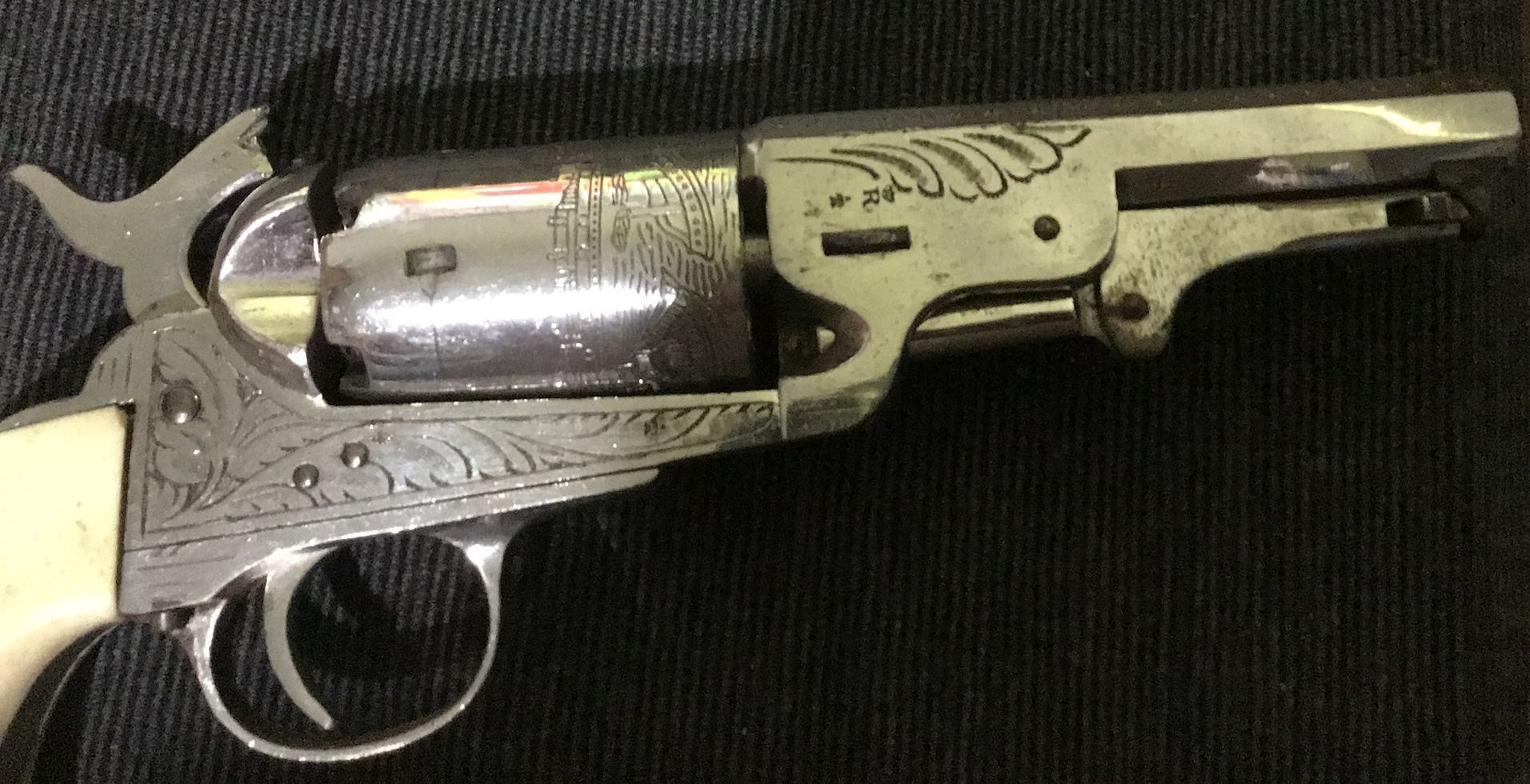

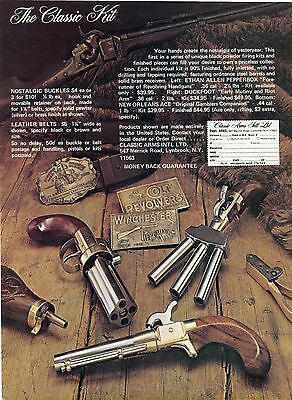

One of the very first and more unusual revolvers was the pepperbox revolver. The pepper-box revolver or simply pepperbox (also "pepper-pot", from its resemblance to the household pepper shakers) is a multiple-barrel firearm, mostly in the form of a handgun, that has three or more gun barrels in a revolving mechanism. While pepperboxes represent some of the earliest revolving firearms, they really came into their own in the 19th century and were mass-produced as sidearms both in the U.S. and Europe. Probably the more well known of the replica pepperbox revolvers was the Classic International Ethan Allen Pepperbox.

Classic Arms International, Ltd. was founded in 1974. Paradoxically, Classic Arms traced its success directly to the 1973 recession. Its founder, president and principal stockholder, Paul Romano, 42, had a long and, until 1973, prosperous career in commercial real estate. Then mortgage money dried up, and Romano found himself with extensive property holdings he could neither sell nor finance. He vowed that his next business would involve only "small-ticket" items that were not as tightly tied as real estate to the overall economy. So guns were his choice.

Romano had been a collector all his life and in had acquired several outstanding antique firearms at four-figure prices. The idea of making reproductions of them intrigued him. "We are manufacturing a better product for less money right here in America, where many of these guns originated," he says. "Some manufacturers get parts from Europe, but our trademark is 'Made entirely in the USA—lock, stock and barrel.'

Romano began producing his own replicas on a limited scale in a small factory in Valley Stream, N.Y., but Classic soon outgrew that plant and in January 1975 moved into an empty 10,000-square-foot factory in Palmer, Mass. that had once produced submarine nets for the Navy. A year later that space had been expanded to 30,000 square feet. Romano's first replicas were of an Ethan Allen Pepperbox, a revolving four-barrel that was used extensively by gold miners and merchants in the 1840s, and a New Orleans Ace, a single-barrel from the same era that was popularly known as "the original gambler's companion."

The response to these weapons was beyond Romano's wildest dreams. His first ads brought in 80,000 orders. More important, a large percentage of those who ordered one gun ordered a second.

Classic produced replicas of four guns, with a fifth, a Derringer adapted to black powder. It also sold a replica of the Coffin Bowie knife and literally tons of silver and brass ornamental belt buckles commemorating everything from Coors beer to exorcism. Gun production alone amounted to from 400 to 600 units a day and were backordered by more than two months. Classic helped lower the unemployment rate in Palmer from 14% to 7.4%.

The reasons for this remarkable success were several, not the least of which was the quality of the products. The guns were not toys, but beautifully machined, precision-tooled products. Depending upon the model, each part underwent anywhere from five to 15 separate operations, all parts were interchangeable within a given model and all pertinent tolerances were held at less than .005 of an inch. This was unprecedented for kits guns.

The surprisingly low cost was another reason for the popularity of Classic's guns. The least expensive model, the New Orleans Ace, sold for $29.95 in kit form, $44.95 completely assembled. The three-barrel Duckfoot, an unusual multiple-shot gun made popular by sea captains who used it to help keep crews in line in the late 18th century, sold for $36.95 for the kit, $54.95 assembled. The double-barrel Snake Eyes, also known as "The Deadly Deuce," a pearlite-handled copy of the favorite persuader of Mississippi riverboat gamblers, sold for $39.95 in kits. $59.95 assembled. One of the most expensive models was the four-barrel Ethan Allen Pepperbox, priced at $44.95 in a kit and $69.95 assembled.

The appeal of the kits was enormous. They outsold completely assembled models by more than 10 to one. The lower cost of the kits was only one reason. Many hobbyists enjoy fitting the parts together, sanding the wood and buffing the metal. Even in kit form the Classic guns were actually 90% completed, fully inletted, drilled and tapped, and require no particular skill, only patience, to assemble. A file, a screwdriver and fine sandpaper were more than adequate to do the job.

"The parts come out like pieces of jewelry," says Neil Gage, Classic's chief design engineer. "Once they have gone through all the machinery, every part is carefully inspected. The guns we build are actually much better in quality and workmanship than the originals. If you paid $500, you would not find any more technical quality control than you get in a Classic gun for $29.95." Classic Arms International, also known as Classic Arms Ltd. also built the Ethan Allen By Hoppe’s single shot .45 caliber pistol for Hoppe’s. It was available in both kit form and fully assembled, but there were issues with the soft hammer spring not being able to always reliably fire caps, and it had a small flash hole channel that often impeded proper ignition and which required drilling it out in order to correct. Sales lagged and Hoppe’s sold the remaining Hoppes inventory of the kits to Numrich Gun Parts Corporation. After they were all sold through Numrich, there were no replacement parts available for the Ethan Allem BY Hoppes pistols.

Unfortunately, in 1977, Classic Arms International fell from grace and by 1978 had filed for bankruptcy. Classic Arms International was eventually sold to Navy Arms during Val Forgett's process of buying out the competition. Val Forgett opened a factory in Palmer, Mass and made Classic Arms guns from around 1979-1983. Navy Arms customers were Best Stores, Otasco, Service Merchandise, Woolco, Spiegel Catalogs and, by far the biggest customer, Kmart. At its peak, Classic was making 10,000 pistols a month. Val Forgett, III told me he remembers as a kid going to the factory with his dad to visit. It was always a fun overnight trip.

When Kmart stopped buying it wasn’t viable to keep the factory running, and Navy Arms moved all the parts in process to Union City, NJ where they were turned into kits. Val, III remembers running the skin packing machine one summer. He said it was not a fun job, he actually preferred working the bluing room.

Navy Arms eventually did sell everything that was left to Erwin Fagel of Deer Creek Products. Val, III was there when they made the deal. Somewhere he still has the spreadsheets his mom did of the parts costings and the production forecasts. It was all done by hand or typed by her at the time on a very modern IBM Selectric typewriter.

So Navy Arms sold off all the remaining stock to Deer Creek Products and Classic Arms was no more. Once Classic Arms had met its demise, Deer Creek Products did pick up the manufacture of some of Classic Arms kits. Instructions and parts for six of the Classic Arms pistols are still available from Deer Creek Products at https://www.deercreekproducts.net/store/c1/Featured_Products.html, but kits are no longer available.

References:

"COLLECTORS ARE GETTING A BANG OUT OF INEXPENSIVE ANTIQUE

FIREARM KITS", Kraft, Virginia, Sports Illustrated, May 23, 1977

Notes from interview with Val Forgett, III