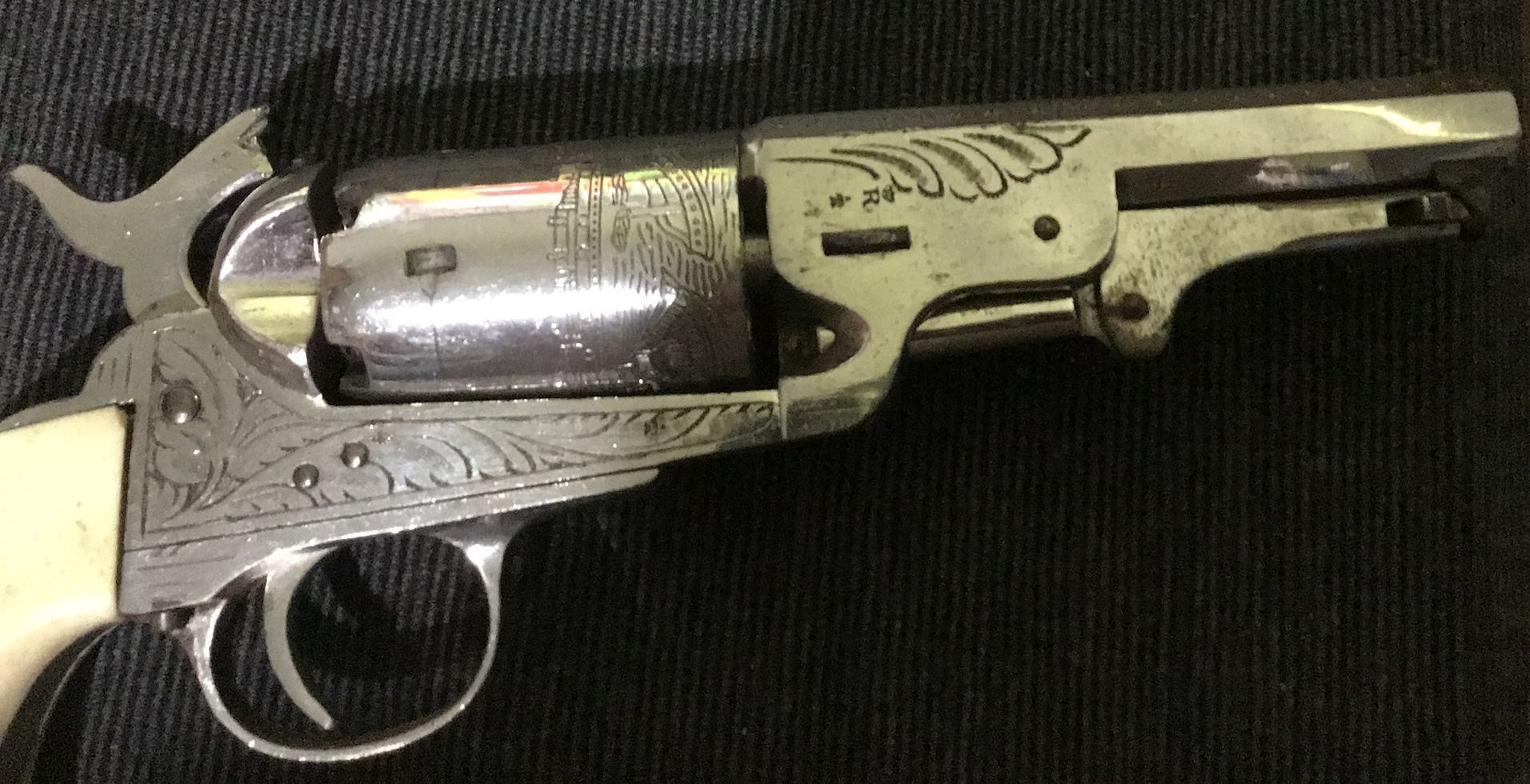

Brass Frame Replica Revolvers

In Praise of Brass Frame Replica Revolvers

While doing some research a few years ago, I came across this article by a fellow cap and ball shooter on his experience with brass framed revolvers. I appreciated his comments and decided it was worthy of sharing. I do not know the author’s exact name, since the article was written under an alias, ORLCL, but I believe it may be Blackie Thomas*, whose YouTube channel can be found here: https://www.youtube.com/user/blackoracle69/videos

"1000 30, 35, 40 grain rounds fired through Pietta 1851 Colt "Confederate" .44 cal brass frame without frame damage/gun loosening. How I did it:"

“I have been into black powder firearms for about 10 years now. Pietta is my favorite for BP revolvers, however I do like the old ASM's just for novelty. It's most important to first note that the BP replica revolvers made by Pietta today (over the last 5 or 6 years) are leaps and bounds higher quality than they used to be thru the 1960's - 1990's. They're just as well built as any other sub-$1000 revolver whether it be made by S&W, Colt, etc. The brass and steel Pietta uses is much stronger than it used to be, the hardening is done better, and the component fitment is tighter. No where else can you find such a well built .44 caliber revolver for $149.99.”

“Now, onto the much debated topic of brass frame .44 revolvers. (The .36 brasser doesn't suffer from the same issues as the .44 though the information can still apply). The brass frame .44's took a bad reputation over the years due to "frame stretching" with reports of people rendering their gun unfireable within 100 shots at only 25 grain loads. Most called this "frame stretching" which is NOT what occurs. The frame doesn't stretch. There are two things which may happen. One: the cylinder recoils backward into the frame when fired. The hammer pushes the cylinder forward when it contacts the nipple, and then the ball leaving the barrel slams the cylinder backward into the frame. Hammering or "peening" the brass at its contact points. Here is an example of a badly peened frame:

As the cylinder loosens up between the barrel and frame, the peening effect worsens. This effect can also occur on loose steel frame revolvers just the same if hot loads are continually used. Eventually it will become so bad that the gun will not fire, or be unsafe to fire.

Second: the steel arbor is threaded into the brass frame. At high loads the arbor will eventually pull itself out of the frame, stripping the threads, and damaging the gun. This is no longer an issue on newer revolvers as the threads are now tapped deeper, longer (more material to thread into), and finer (more surface area). With a tapered pin hammered and brazed into a notch on the rear arbor, further adding to the strength of the arbor to frame connection. As a matter of fact, this used to be an issue on BOTH steel and brass frame revolvers, it wasn't just brass.”

“Now, Pietta doesn't actually make the brass or steel they use. Stock is purchased from a materials supplier, then Pietta works it to the components they need. The brass used in frames today is considerably stronger than that of past revolvers. I'm awaiting a response from Pietta on the type of brass used, but it's most likely C360 "Free Machine Brass" which has a high zinc content, and also has a small amount of tin and lead making for a very hard brass product which can be machined easily however it is not very malleable: AKA not flexible, will not bend and compress easily. (Although it could even be C464 "Naval Brass" which is even stronger.) The yield strength of these two brasses nearly matches that of many types of mild steel, though the tensile strength of steel is considerably higher and hardening/forging increases this as well. The steel used in steel frame Pietta's is case hardened mild steel, it is not forged. The brass used in older guns was far more inconsistent, often it contained very low quantities of zinc, no tin at all, making for a soft product. Not good for the hammering forces of a .44 round.”

“Frames are first cast into the overall shape to create frame blanks, then they are loaded into CNC machinery which mill the blanks into the desired form. The computer of course is highly precise and does not make mistakes. The final assembly, fitting, and polishing is all done by hand with the help of some powered machinery. This hand fitting can result in some differences of the final product: mainly the cylinder to barrel gap. In Pietta revolvers this usually ranges between .006" and .012". All safe ranges when only shooting 15 grain loads, however if you want to shoot hotter loads without damaging your gun, tighter is important. When purchasing a revolver it's important to examine several different ones of the same model to choose the tightest one.”

***Before going any further, if you have zero mechanical/metalworking experience and/or no confidence in your ability to learn how to work on guns then I do not recommend attempting this yourself. Have a gunsmith do it, or simply leave your gun as is.

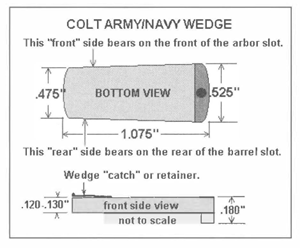

“Keeping the cylinder to barrel gap tight is the most important thing to prevent your brass frame revolver from peening. My gun was a bit of a lemon as it had a .014" gap from the factory. I have my cylinder to barrel gap set at .003" which is tight enough that there is no noticeable play in the cylinder at all. Having it that tight also prevents less gas from escaping, resulting in a more powerful shot. Although some recommend .004" with BP. To tighten the gap, the end of the arbor is filed. It doesn't take much, so carefully file a little at a time and test fit. It's very important to keep the file level to maintain a flat surface. Also the barrel lug will need material removed as the arbor is shortened. The two steel pins can simply be pulled out. I like to leave the lug about .001" to .002" longer than the arbor, this creates a tighter fit when the wedge is assembled. As material is removed from the arbor the wedge will fit deeper in. If your starting point is only .008" and you go to .004" then your original wedge will work fine. Since my gun was .014" factory I put a small weld at the front of the wedge slot on the arbor, then filed it as needed to properly fit the wedge. A thin steel shim can also be made to slide on the front part of the wedge instead. The wedge is only used to hold the two halves of the gun together, it is not used to adjust cylinder gap (as seen with Uberti). The arbor should be fully seated in the barrel, and the wedge lightly tapped in. This creates a tighter more consistent fit which will result in greater accuracy. The length of the arbor controls cylinder gap, not the depth of the wedge.”

“Another thing I like to do is put a nice coating of bore butter on the contact points between the back of the cylinder and the brass ring where it rides on the frame. This will tighten the gap even further and create a cushioning effect when firing. Also it keeps fouling soft.”

“Something else you can do to tighten the side to side play of the cylinder is to put a very thin shim between the top of the trigger spring and the bottom of the bolt (the two fingered spring that locks the cylinder bolt + trigger in place). This will push the bolt up with more force, locking the cylinder in even tighter when the hammer is cocked. And by thin I mean like thin as a razorblade. I used a piece of a pocket watch mainspring, though most of us don't have those laying around. Cutting down a small strip of razor blade will work well.”

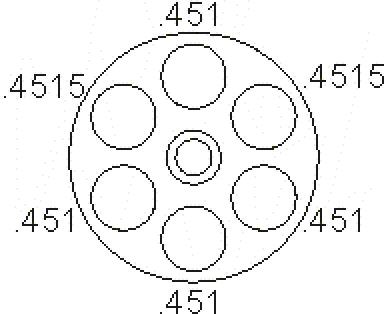

“As I stated in the title, I've fired about 1000 rounds through my Pietta 1851 brass frame revolver. I typically shot 30 to 35 grain loads though I've gone up to 40. Also much of the time I was using Triple 7, which is considerably more powerful than BP (though classic FFFg BP is my favorite). I also shoot .457 round balls which form a much tighter fit than .451 or .454, further increasing the forces involved in a shot. I've taken big bucks with this pistol, coyotes, groundhogs, squirrels, and other vermin. It's even my home defense firearm. The 44 caliber soft lead roundball has significant stopping force. I roll up paper cartridges with 30gr powder, corn meal, .457 ball, using magnum percussion caps. Using my paper cartridges + capper I can reload all 6 chambers nearly as fast as someone can unload and reload a .357 magnum.”

“I hope I've helped to dispel some of the inconclusive information floating around out there on these brass framed revolvers. Brass frame guns are my absolute favorite, so if you like brass as well do not shy away from that shiny new brass framed Pietta!”

*The author is indeed, Blackie Thomas and this has been used with his permission.