Colt Black Powder Reproduction Revolvers - A Consice History

A Concise History of the Colt 2nd Generation Black Powder Reproduction Revolvers

To this day, there is still much confusion as to the manufacture of the Colt 2nd Generation Black Powder Reproductions, known as the “Authentic Colt Black Powder Series” made by Colt’s Manufacturing and the 3rd Generation Black Powder Reproductions known as the “Signature Series”, marketed by Colt Black Powder Arms Co. It can be rather confusing, since there were actually three separate productions of the Colt Blackpowder Reproductions that were made. Hopefully, this article may help clear up some of the confusion.

The start of the 2nd Generation Colt Revolvers actually began in 1956. The Colt Single Action Army (SAA), adopted by the military in 1873, had become one of the most iconic firearms in U.S. history. Production of the Colt SAA began in 1873 and did not cease until about 1940, at the outbreak of WWII. But the gun did see some action in World War II, being carried at times by such notables as Gen. Jonathan M. Wainwright, Gen. Douglas MacArthur and Gen. George S. Patton.

When the SAA production ended, the machinery that made these formidable revolvers was stored in a corner of the Colt plant. But after WWII and the Korean War, in 1956, Colt pulled that machinery out of the corner of the plant and began making the SAA again. With serial numbers ending in SA, we had the birth of the Colt "2nd Generation" SAA.

In 1971, due to the success of the SAA "2nd Generation", Colt was persuaded to re-introduce its Percussion Colt Revolvers again, making use of the machinery that had made certain parts of the SAA. And the 2nd Generation "C" Series was born.

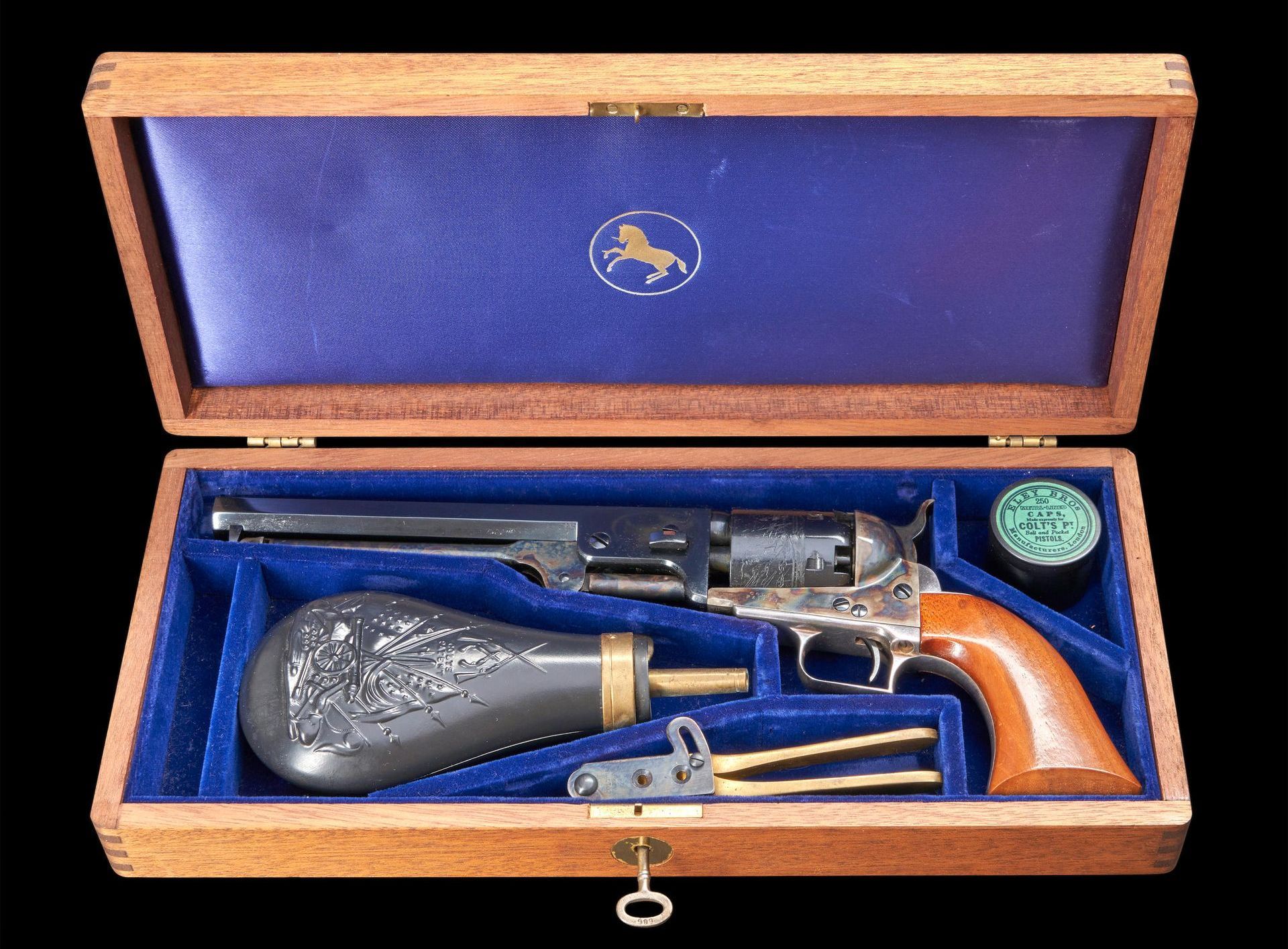

The production of the Colt 2nd Generation Black Powder reproductions took place in three stages. Initially, Colt Industries tested the waters with Val Forgett's help to build their first "C" Series 1851 Navy reproductions in the 1971-1973 time frame, which had included the now very collectible Grant and Lee Navy sets. These revolvers had the barrels, cylinders, and backstraps rough cast in Italy, but were finished off at Colt's facilities in Hartford, CT. where Forgett had the frames, the center pins, nipples, all of the screws, and springs made and built for every "C" Series gun at Colt Manufacturing. Each 2nd Generation part was meticulously tracked and quality inspected at the Colt factory. However, in late 1973, Colt Manufacturing Co. decided to seek a new supplier of components, and Lou Imperato, Colt's largest distributor at the time, was chosen to take over production.

Beginning in 1974, Lou Imperato replaced Val Forgett as Colt's supplier of components to build their percussion revolvers. These revolvers were completed in exactly the same way as all of their previously made 2nd Generation percussion revolvers – at Colt facilities - from 1974 to 1976. They had the barrels, cylinders, and backstraps cast in Italy, and were finished off at Colt's facilities in Hartford, CT. where Imperato had the frames, the center pins, nipples, all of the screws, and springs made for every "C" Series gun. Each 2nd Genertion "C" Series part was meticulously tracked and quality inspected at the Colt factory.

The guns produced in this time frame were packaged in wood grain, cardboard boxes. The relationship with Imperato continued until Colt discontinued their entire "C" Series line of percussion revolvers in 1976. Just prior to that time, the SAA 2nd Generation era came to an end in 1975, at about the 74,000 serial number range and the "C" Series then followed followed in 1976. Colt made this decision due to the original machinery becoming badly worn and was beginning to “chatter.”

It was in 1977/78 that a new relationship was born and Imperato began manufacturing the 2nd Generation "F" series percussion revolvers at Iver Johnson Arms Middlesex, NJ, which he then owned. It was there that all "F" Series standard production models were manufactured as The Authentic Colt Blackpowder Series, just as the “C” Series had been. While being built in considerable numbers, the guns were far from mass production, with each, as Imperato later explained to Colt, was virtually hand finished. "They were all hand fitted. We had the barrels, cylinders, and backstraps cast in Italy (as Forgett had done), but we finished them off in house. We made the frames, the center pins, nipples, all of the screws, springs, and built every "F" Series gun at Iver Johnson Arms. We even used the old style color case hardening method with the charcoal and bone meal, and Colt's exclusive Colt Blue Finish for the "F" Series. They turned out pretty good. In fact, I think our finishes were actually better than Colt's single actions being done in Hartford," says Imperato.

These new "F" Series 2nd Generation models came in black cardboard boxes with dark grey foam rubber inserts, and featured Sam Colt's portrait and signature on the lid and end label. This relationship with Imperato continued until Colt discontinued their entire "F" Series line of percussion revolvers in 1982.

In Review

Stage one was during the period when Val Forgett and Navy Arms built the revolvers in Colt facilities from 1971 -1973. Stage two was when Lou Imperato built the revolvers in Colt facilities from 1974 -1976, from the same source as Val Forgett. And stage three was from 1978 -1982, when Lou Imperato supplied these parts, but with the barrels, cylinders, and backstraps cast in Italy and the frames, center pins, nipples, all of the screws, and springs made in the United States at Iver Johnson. All the percussion models made from 1971 to 1982 either by Colt, or its subcontractors are regarded as authentic Colt revolvers and not Italian replicas.

The 3rd Generation Signature Series

At the end of the contract with Lou Imperato to assemble the 2nd Gen Colts, Lou Imperato was already working on a contract with Colt to produce the 3rd Gen Series. Evidently Lou considered the possibility of having Uberti make the completely finished gun. A series of sixteen revolvers of different models were made by Uberti with all the Colt markings. Each one carried a license "permission" letter from Colt. Finish is Royal Charcoal Blue over highly polished metal. These do, however, have the Uberti name under the loading lever. Colt could not accept this and then rejected Mr. Imperato's proposal. The approval letters are dated Jan.15, 1990 based on the contract between Iver Johnson and Colt dated July, 1985. These sixteen revolvers are highly collectable today.

Most Colt collector’s accept the 2nd Gen revolvers as real Colt's and consider these collectable. A number of collectors, however, do not accept the 3rd Gen revolvers as Colts and thus the difference in value. The demand for 2nd Gen revolvers is by both Colt collectors and replica percussion revolver collectors, whereas, the demand for 3rd Gen revolvers is by the replica percussion revolver collectors and ignored by Colt collectors. I might add the demand for these Colts by shooters also play a big part. Since these 2nd & 3rd Gen revolvers are modern production, many of them are still available in “New In Box” condition. These are the ones wanted by collectors. Fired revolvers will be discounted by 50%.

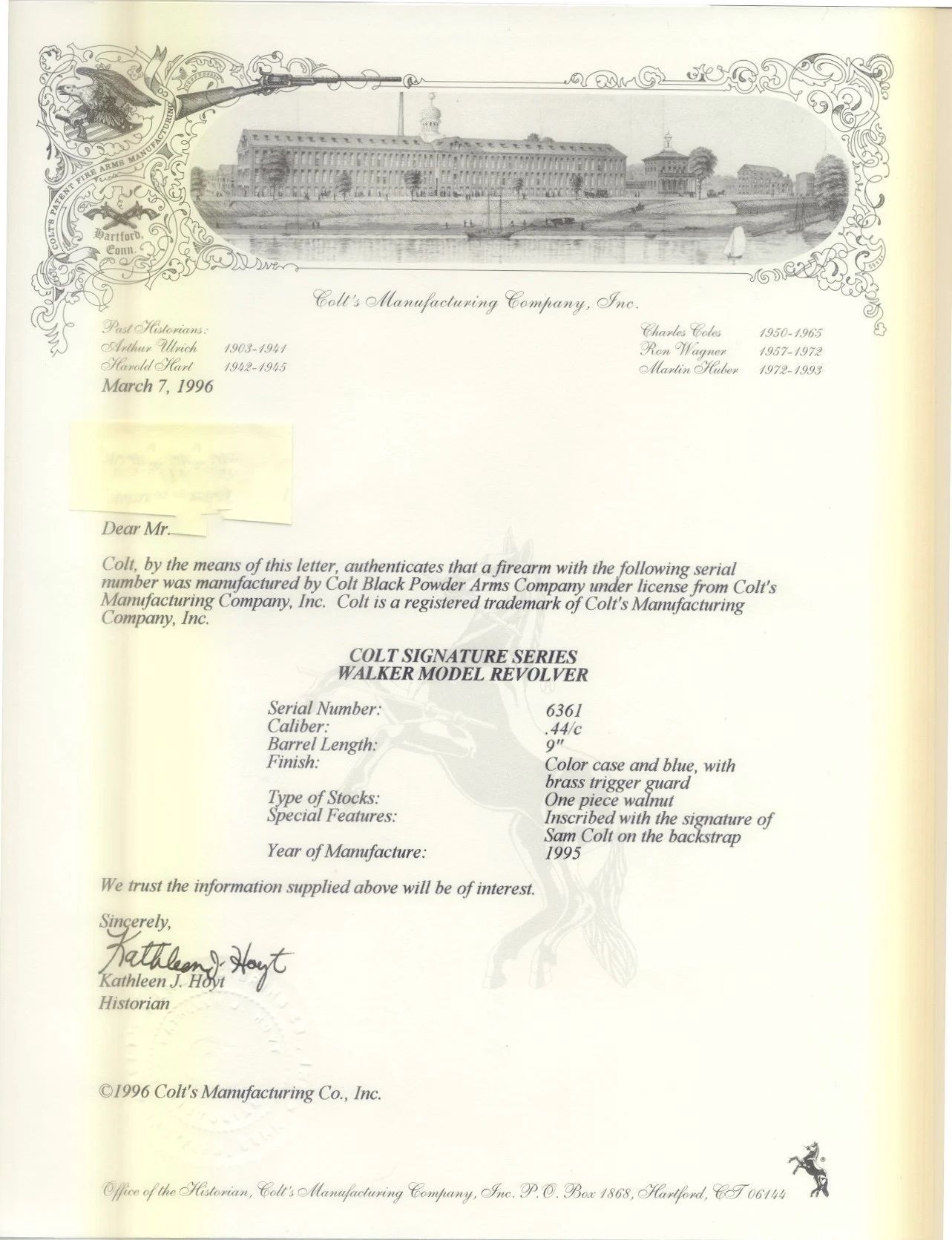

It wasn't until 1993 that Lou Imperato formed the Colt Blackpowder Arms Company to create what became the 3rd Generation Series. Known as the “Signature” Series, the 3rd Generation Series was under a "licensing" agreement with Colt Manufacturing, but had no connection to Colt at all, except for the use of Colt's licensed name. Under this “licensing” agreement, Imperato at his Iver Johnson factory where the 2nd Generation "F" Series were produced, was responsible for procurement of all parts, which came from Uberti and Armi San Marco, as we have found out, in Italy. Iver Johnson was also responsible for quality control, final inspection, marketing, advertising, sales and distribution of the revolvers. This was a totally different agreement than either Forgett or Imperato had for the “C” Series or the “F” Series and these “3rd Generation” revolvers were never affiliated with Colt Manufacturing and Colt Manufacturing will not recognize them nor letter these revolvers except on very, very rare occasions. Colt will letter those revolvers that have a complete series of manufacturing, final inspection and quality control records that satisfy the Colt requirements for lettered revolvers. These records are available for very, very few 3rd Generation revolvers.

This statement is supported by an article published in the November 1994 issue of "Gun Tests" magazine. It revealed that "Colt's Manufacturing Co., apparently concerned that its customers might be confused by similar names, says it has nothing to do with black powder guns being sold under the 'Authentic Colt Black Powder Signature Series' name." They went on to quote Jeff Crute, Colt's Vice President of Sales and Marketing. He is reported as stating "The guns are manufactured and marketed by John J. Jovino and Co. of New York (owned by Lou Imperato) and bear only the Colt name. The (revolvers) are being produced and sold through a special licensing agreement which was negotiated prior to the current management ( in 1994). CMCI (Colt's Manufacturing Co., Inc.) assumes no responsibility for product quality, workmanship or liability."

It is this 3rd Generation Series, made between 1993 and 2002, that has created most of the confusion as to whether or not these “Signature Series” of revolvers were Italian made. Yes, the 3rd Generation Series parts were completely Italian made by Uberti and later a few by Armi San Marco and then assembled at the Iver Johnson factory by Colt Blackpowder Arms Company of Brooklyn NY.

An interesting side story to this 3rd Generation Series is that Lou Imperato left Armi San Marco holding the bag on a bunch of parts ordered by Colt Blackpowder Arms when they went out of business in 2002. Most were barrels that had been marked with the Colt Address. Rather than eat them ASM put them on their own revolvers that they were exporting to the U.S. You have a well finished Armi San Marco revolver with the official Colt Address on the Barrel and "San Marco" on the frame where the "Colt Patent" usually is found. These are extremely collectable and are already bringing some high dollars from replica revolver collectors. Customs put a stop to these imports when Colt Complained, but some got through customs.

Further Evidence:

A Colt's Firearms "Summary of Operations" document explains how each percussion revolver was built. This 120 page factory manual was originally dated October 19, 1970 and shows various revisions and approvals up to January 15, 1973. It begins with a minutely detailed outline of how rough parts were to be uncrated and kept in groups of fifty after their arrival at Colt's Connecticut factory. It goes on to describe the logging in process, application of serial numbers on specified parts, stamping of "Colt's Patent" on the frame, roll marking the barrel address and roll engraving the cylinder scene. Then it proceeds step by step through the process of how each part or assembly should be filed, fitted, rough polished, match polished, blend chamfered, finish polished, color case hardened, blued, silver plated and assembled. It even names what piece of Colt's machinery or equipment to use for each manufacturing step. Further, it describes how walnut grips were serial numbered inside the backstrap inlet with an indelible pencil and then sanded, cleaned, stained, sealed an coated with a clear lacquer that was supplied by Haines Laboratories, Inc. in Chicopee Falls, MA.

Rough castings and semi-worked parts were acquired from both American and Italian subcontractors as well as through in-house fabrication. They were then processed according to Colt's directives in the same manner as described in the above. Colt Firearms Engineering Specification# CS1030 gave detailed requirements for safety, performance, appearance and function of black powder revolvers. This document was continually revised with upgraded standards throughout the "C" Series and "F" Series production time frame.

While touring the Colt factory in 1992, Dennis Russell had the opportunity to visit with an elderly worker in the case hardening furnace room at Colt's. Having noticed unfinished pieces of a Colt 1847 Walker revolver attached to the wall, he was inspired to inquire about Colt's participation in the finishing process of their 2nd Generation percussion revolvers. The elderly worker confirmed that, years earlier, he personally had been involved with the case hardening of Colt percussion gun parts. In addition, a recently discovered archive of Iver Johnson files confirms the fact that "F" Series frames, loading lever assemblies, and hammers were regularly shipped for case hardening from Iver Johnson's Middlesex factory to Colt's manufacturing facilities in Connecticut. This archive also demonstrates how each 2nd Genertion part was meticulously tracked and quality inspected. If the part was substandard, it was either returned for rework or discarded. A review of this information on the production of Colt Second Generation Percussion Revolvers indicates that it is clearly a Colt.

For further study, there are two excellent books written on the subject of the Colt Black Powder 2md Generation Series. Dennis Russell’s book, “Percussion Colt Revolvers – The Second Generation – Collector’s Handbook & Price Guide” and Eric Deaton's book “Collecting Modern Colt Blackpowder Revolvers”.

Dennis has continually revised his book and the last edition I have is #6. It is laid out in a format that makes it easy to find information about specific questions that arise. It is the only source of information about the accessories, special editions, display cases, and even the packaging the revolvers originally came in and their values. Dennis publishes this book himself so it is only available from him direct. Ordering information is available at the Endnotes Section of this document.

Eric Deaton's book

is a second text on collecting the Colt 2nd & 3rd Generation Blackpowder revovlers. With hundreds of color pictures (several in full scale) this nearly 300 page book shows you how to tell them apart, how they work, what is rare and how they were packaged. With chapters on collecting, comparisons, packaging and accessories you will learn how to tell the best revolvers from the run of the mill ones. Deaton's book is available from eBay at

https://www.ebay.com/itm/284088354994

Endnotes:

“A History of Colt Black Powder Reproductions” by Dennis Adler

“Ninth Edition Blue Book of Modern Black Powder Arms” by John B. Allen and S.P. Fjestad with introductions to Colt’s Manufacturing Company and Colt’s Black Powder Arms Co. by Dennis Russell. The author and publisher wish to thank Mr. Dennis Russell for his valuable assistance updating the previous information from the section of the Blue Book of Modern Black Powder Arms.

Russell, Dennis. “Yes - They Are Real Colt's.” Percussion Colt Revolvers The Second Generation Collector's Handbook & Price Guide #6, by Dennis Russell, Jared Press, 2013, pp. 12–14.)

“COLT An American Legend” by C.R. Wilson.

Russell, Dennis. Percussion Colt Revolvers The Second Generation Collector’s Handbook & Price Guide #6. Jared Press, LLC, 2013.

~ The 6th edition of Percussion Colt Revolvers – The Second Generation – Collector’s Handbook & Price Guide is available for immediate delivery. The price is $39.95 plus $7.50 for shipping and handling charges to the lower 48 states (slightly higher shipping charges for Alaska, Hawaii and other parts of the world). If you are located in the lower 48, just send your $47.45 check or USPS Money Order to the address below. If you are located elsewhere, please provide your address and I will be happy to quote you the shipping charges for that location. IMPORTANT: All checks or USPS Money Orders must be made payable to Dennis Russell.

Dennis Russell

c/o Jared Press, LLC

3162 Johnson Ferry Road

Suite 260 – 607

Marietta, Georgia 30062

The shipping method quoted above is USPS Media Mail. If you prefer a faster method of shipping, upon request, he will be pleased to provide a quote for that service.